Specifications of High Quality Custom Jig And Fixtures Tooling CNC Machining Component

Type: | Broaching, Drilling, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM | Material Capabilities: | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys, plastic |

Micro Machining or Not: | Micro Machining | Model Number: | OEM |

Size: | 48mm*57mm | Material: | AL6061-T6 |

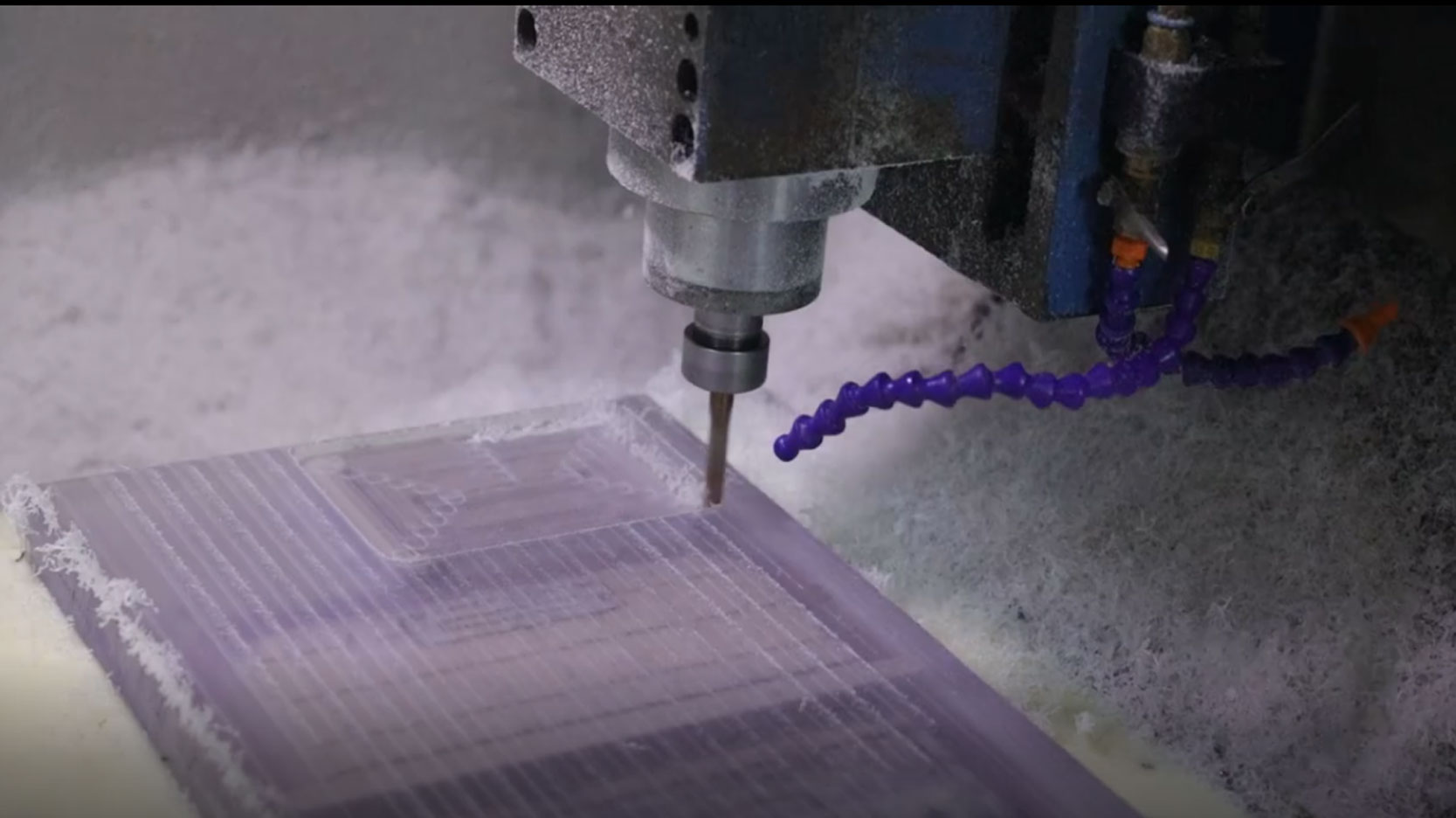

Main Process: | Aluminum CNC milling | Surface treatment: | Clear anodizing |

Tolerance: | +/-0.005mm | Supply Ability | 1,000,000 Pieces per Month |

As the finishing process will affect the surface finish (thus affecting the part size), we do not recommend the application of secondary finishing on high tolerance parts, because the finishing process may remove or add enough materials to make the finished parts exceed the dimensional tolerance. DF provides the following secondary processing for your machining and sheet metal processing parts.

Chemical film coating: also known as chemical conversion coating, chromate coating or zinc coating, aluminum or nickel coating. The surface produced by this process has corrosion resistance, durability, and stable conductivity.

Anodizing: anodizing is an electrochemical process that transforms aluminum (usually aluminum) into a decorative, durable, corrosion-resistant anodized surface.

Powder coatings: textured powder coatings (spandex polyester and textured polyester) will cover tool marks without additional surface treatment.

Texture finish: deburring and scraping parts with a brush/sander to create a specific texture. It is ideal for parts where a uniform nude finish is necessary, but powder coating is not ideal. Due to the geometric shape, grain size finishing can only be applied to the outer surface of parts processed by numerical control and sheet metal, but not to the inner surface of parts. Non-textured coatings (smooth polyester, smooth epoxy, and smooth polyester epoxy) will not cover tool marks by themselves. Therefore, an additional finishing operation, such as grain size finishing, needs to be performed.

Number printing: This is Ideal for branding (such as your logo), label connectors and switches, and decorative purposes (silkscreen can also be used as an alternative to digital printing).

Machining engraving: This is a permanent form of marking, very suitable for labeling, branding, or schematic. Also known as etching, machining, engraving can be done with powder coating, paint, particle finishing, anodizing and chemical film chromate coating, depending on the material.