Specifications of High Quality 5 Axis Stainless Steel/Brass/Aluminum/Titanium CNC Precision Machining Parts

Type: | Broaching, Drilling, Etching/Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM | Material Capabilities: | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys, plastic |

Micro Machining or Not: | Micro Machining | Model Number: | OEM |

Size: | 55mm*45mm | Material: | 4140 steel |

Main Process: | Aluminum CNC milling | Surface treatment: | Clear anodizing |

Tolerance: | +/-0.005mm | Supply Ability | 1,000,000 Pieces per Month |

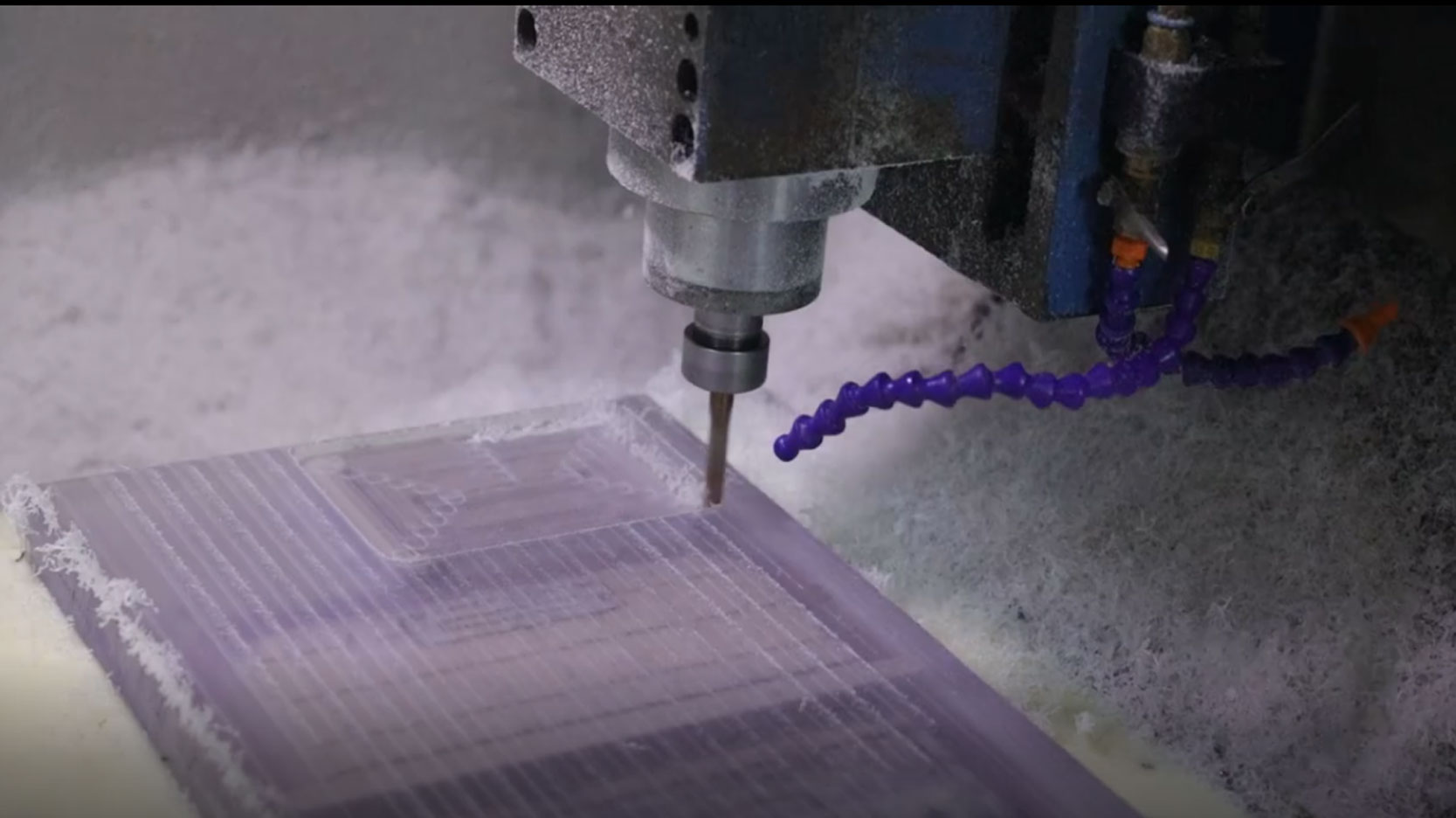

What is five-axis CNC machining?

5 axis machining has a unique ability to effectively process the size and shape of parts and basically has unlimited possibilities. Like the 3-axis machine tool, the tool of the 5-axis machining center moves on the X, y, and Z linear axes, but also rotates on the A and B axes, allowing the tool to approach the part from any direction. An experienced mechanic can achieve incredibly complex geometry with high precision using all 5-axis combinations. Skilled and experienced CNC Machinists and programmers are able to process complex shapes, undercuts, and angles - all of which can be activated in one setup.

The ability to process a part in one installation not only improves the accuracy in the process of processing but also reduces the tool cost, indirect cost, and labor time, so as to make the cost of each part as low as possible. Five-axis machining center eliminates some shortcomings of traditional CNC machining technology, including multiple settings, parts transfer and inspection; Parts handling, and errors related to human involvement/interference.